The robotics field is experiencing exponential growth, fueled by advancements in artificial intelligence (AI), machine learning (ML), and increasingly sophisticated hardware components. A critical, yet often overlooked, element in the success of any robotic system is the selection and proper application of gear motors. These motors are the unsung heroes, translating electrical energy into the precise and powerful motion required for everything from delicate manipulation to robust locomotion. Choosing the right gear motor, and understanding how to calculate its performance parameters, is paramount. This article will delve into the essential selection points and calculation methods for gear motors, specifically focusing on the considerations relevant to robotics applications, and highlighting how companies like MES-Drive are contributing to this critical area.

Gear motors consist of an electric motor coupled with a gearbox. The gearbox reduces the motor's high speed and torque, providing the necessary output characteristics for robotics tasks. They offer a significant advantage over direct-drive motors in many robotics applications, enabling:

The demand for high-performance gear motors is soaring, directly linked to the rise of applications ranging from warehouse automation and delivery robots (reflecting the ongoing e-commerce boom) to surgical robots and advanced industrial manipulators.

Choosing the right gear motor isn’t a one-size-fits-all exercise. Several factors must be carefully considered:

Torque Requirements: This is arguably the most important parameter. Robotic applications have diverse torque needs. A robot arm performing precise pick-and-place operations will require different torque capabilities than a mobile robot navigating uneven terrain. Accurately estimating the required torque, considering static load, dynamic load, and potential acceleration/deceleration, is crucial. Overestimating can lead to unnecessary cost and size, while underestimating will result in performance bottlenecks.

Speed Requirements: The required speed depends on the task. High-speed applications, like rotating components or fast linear actuators, require motors with high RPM (revolutions per minute). Conversely, applications needing precise positioning, like joint control in a robot arm, benefit from lower speeds.

Gear Ratio: This ratio dictates the trade-off between speed and torque. A higher gear ratio results in lower speed and higher torque, and vice-versa. Selecting the appropriate gear ratio is vital for matching the motor’s output to the application’s demands. Robotics often necessitates a careful selection of gear ratios for optimal performance across different motion profiles.

Efficiency: Energy efficiency is critical for battery-powered robots and for minimizing operating costs in industrial settings. Look for motors with high efficiency ratings, ideally exceeding 85% for optimal performance.

Size and Weight: Especially crucial for mobile robots and space-constrained applications, size and weight must be carefully considered. Integrated gear motors offer compact solutions.

Mounting and Integration: Consider the motor's mounting interface and how easily it can be integrated into the robotic system. Standardized mounting options simplify the assembly process.

Environmental Considerations: Robots often operate in harsh environments. Ensure the motor is rated for the required temperature range, humidity levels, and potential exposure to dust, water, or other contaminants.

Accurate performance calculations are essential for selecting the appropriate gear motor and ensuring optimal system performance. Here are some key calculation methods:

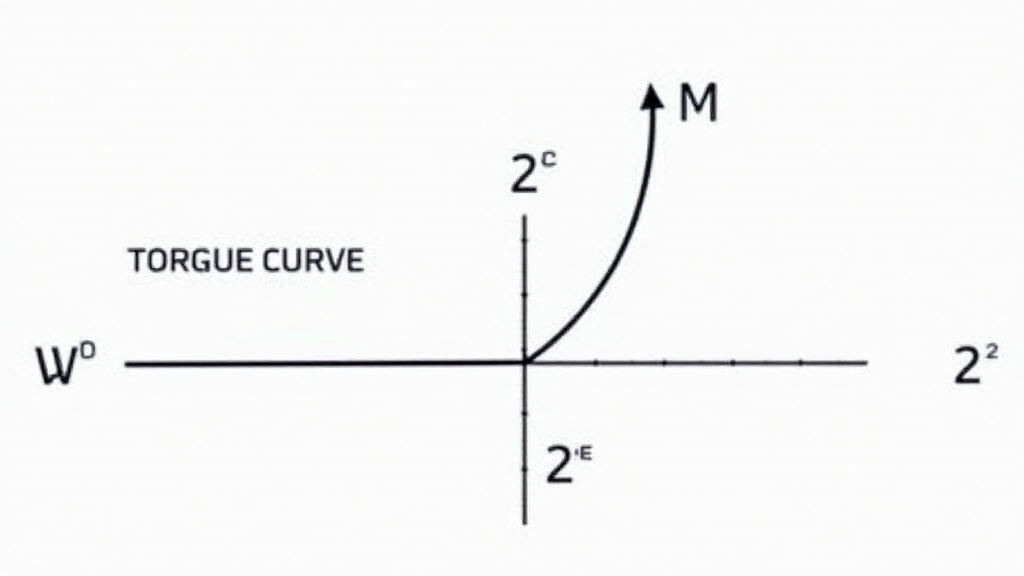

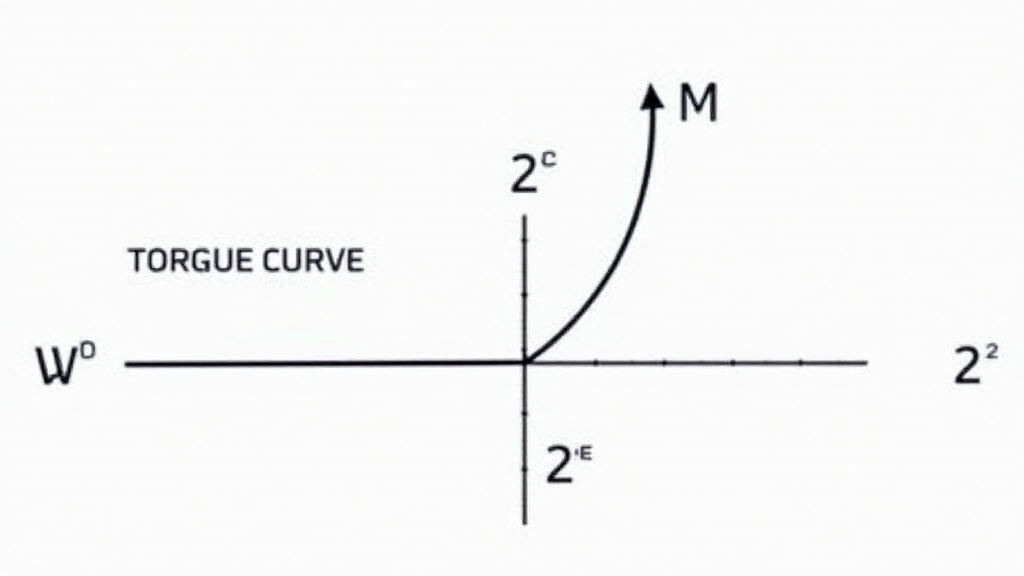

Torque Calculation:

Tdynamic = Tstatic + J * α where:J is the moment of inertia of the load.α is the angular acceleration.Speed Calculation:

ωout = ωmotor / gear_ratio. Where ωmotor is the motor's output speed.Power Calculation:

Pin = U * I * cos(φ) where:U is the motor voltage.I is the motor current.φ is the power factor.Pout = T * ωout where:T is the output torque.ωout is the output speed.Efficiency = Pout / Pin.Gear Ratio Selection: The gear ratio is often determined by balancing the speed and torque requirements of the application. A design optimization process is typically used to find the optimal gear ratio for maximizing performance and efficiency. Simulation tools are often employed for this purpose.

Companies like MES-Drive are at the forefront of developing innovative gear motor solutions specifically designed for the demands of the robotics industry. Their product range encompasses a wide selection of high-efficiency, compact, and robust gear motors, often integrated with intelligent motor controllers, streamlining the integration process for robotics developers. MES-Drive’s focus on minimizing backlash and providing precise control is particularly relevant for applications requiring high accuracy, such as collaborative robots working alongside humans. They are also investing heavily in motors designed to withstand the rigorous conditions of industrial automation environments.

Selecting the right gear motor for a robotics application is a complex process involving careful consideration of multiple factors. Understanding torque requirements, speed demands, and efficiency metrics, coupled with accurate calculation methods, is essential for achieving optimal system performance. The rise of advanced robotics, particularly in fields like logistics and healthcare, is driving increasing demand for high-performance gear motors. Companies like MES-Drive are playing a crucial role in this evolution by providing innovative and reliable solutions.

As AI and ML continue to advance, the demands on robotic hardware will only increase. This creates significant opportunity for companies specializing in gear motor technology, particularly those focused on efficiency, precision, and robustness. The convergence of AI and robotics promises a future where gear motors will be even more integral to the success of intelligent, autonomous systems. The focus on energy efficiency, coupled with the advancements in motor control algorithms, positions MES-Drive and similar innovators to lead the way in powering the next generation of robots.

Leave A Reply

Your email address will not be published. Required fiels are marked